Have you ever heard the term “overheating prevention” ?

It’s not something you often hear in daily life, but in fact, it’s a function that’s used quite close to us.

We also get many inquiries from customers saying, “It would be a big problem if the temperature gets too high!”

So today, I’d like to introduce what overheating prevention is and show some familiar everyday examples.

Overheating prevention is an essential function for heaters!

As the words suggest, overheating prevention means “preventing the temperature from rising too high.”

There are actually many situations where “you absolutely don’t want the temperature to rise beyond a certain point,” and devices that use heat often have this function built in.

Since we are “heater professionals” who manufacture equipment that uses heat, this function is truly indispensable.

Without it, temperatures could rise too high and even cause a fire!

In fact, we receive many inquiries like “Won’t the heater temperature rise too much?”. Which shows how important and necessary this function is for users as well.

In confectionery, temperature is everything! Watch out for overheating!

When it comes to familiar examples of overheating prevention, it’s often used in situations where overheating might cause a fire. But it’s also used to “protect taste and quality.”

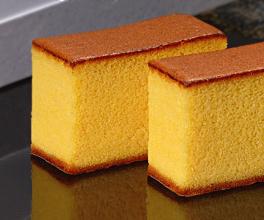

A prime example is making sweets.

Confectionery is very delicate and just slight differences in amounts or temperature can drastically change flavour and quality.

The most important factor here is temperature.

For example, when making castella sponge cake, mixing eggs, sugar, and flour must be done at 23–28℃. When baking, the oven switches between 180℃ and 150℃.

If the temperature suddenly rose above 200℃, both appearance and taste would be ruined.

That’s why ovens often include a PID controller to maintain stable heating and prevent sudden overshoot. This is another way in which overheat protection helps everyday life.

ThreeHigh heaters are hard at work in confectionery production too!

In fact, our heaters are also widely used in professional confectionery manufacturing.

As mentioned, temperature control is essential in confectionery making.

At ThreeHigh, we receive many inquiries from confectionery sites and provide heaters optimized for their processes.

Examples include:

-

Warming tanks filled with syrup to make it easier to knead

-

Heating piping so syrups flow smoothly

-

Melting chocolate to precise temperatures, and much more

By providing heaters tailored to different needs, we help support delicious confectionery production.

Heating with heaters, overheating prevention with “monoOne-120”!

At ThreeHigh, we not only provide various heaters but also supply products designed with overheating prevention in mind.

For cases where temperature adjustment is difficult with just a heater, or where the temperature must never exceed a certain point, we recommend our temperature controller “monoOne-120.”

Features of the monoOne-120:

-

Dual-screen temperature display with monitor

Equipped with two temperature sensors, it can display both the heater and the object being heated. This allows you to monitor the heater temperature while also measuring the item being heated. -

Timer function

Allows you to set the heater to start or stop heating after a certain time (up to 100 hours, in 1-minute increments). With this, the device can automatically run or stop even without people present. (Optional function, +2,200 yen.) -

Industry-first 5-year product warranty

While most controllers only come with about 1 year of warranty, the monoOne-120 offers a long 5-year warranty for peace of mind.