White rice is indispensable for home meals and catered lunches. For white rice, a rice miller uses a rice milling machine to process brown rice into white rice and wholesale it.

Well, people involved in the rice milling industry have a certain difficult problem in their daily work. This is a rice bran remover that adheres to the inside of the rice mill. Adhered rice bran must be cleaned manually on a regular basis, which is time-consuming and labor-intensive. Although they want to change this cleaning works, but they cannot find a good method. Eventually, they end up doing manual works as usual.

Heating with a heater is effective in removing adhering rice bran. Therefore, we will introduce the removal of rice bran in the rice mill using a heater, which can be said to be good news for rice millers.

Adhesion of rice bran inside the rice mill is a cause of concern

The white rice we eat on a daily basis is made by removing the bran (rice bran) and the germ from the raw material, brown rice. The process of turning brown rice into white rice is called rice polishing. To polish the rice, a special machine called a rice polishing machine is used.

↑commercial rice milling machine

When you put brown rice into the rice milling machine and operate it, the machine takes in air and creates a strong air current inside. When the brown rice collides with each other due to the air current, the rice bran and germ on the surface of the brown rice are peeled off. The grains that are left after these are peeled off are white rice. The white rice is collected in the built-in rice polishing tank.

On the other hand, the rice bran is separated from the brown rice in the rice milling machine, turned into powder, and sent to the tank where the rice bran is collected. Some of the powdered rice bran adheres to the piping in the middle of this process. Approximately 20% of rice bran is oil and fat, and it is sticky rather than smooth. Therefore, the rice bran sticks to the inside of the piping due to the stickiness of the oil.

↑Inside of piping

If the rice bran that has accumulated in the piping is left as it is, the rice bran will be exposed to air and oxidized, resulting in a darkening of the color. This is unhygienic. This is because part of the blackened rice bran may fall off during the rice polishing process and mix into the rice container. If products are shipped without noticing contamination, consumers and business partners will question hygiene management. For rice millers, it can be a credibility problem, so they are very concerned about the adhesion of rice bran.

The cleaning work of adhering rice bran is a large task

In order not to mix the blackened rice bran with the white rice, the rice mill must be cleaned regularly to remove the attached rice bran.

Rice bran mainly adheres to the piping of the rice mill. Stop rice milling machine for cleaning. After that, the cleaning door inside the pipe is opened and the rice bran is removed by air pressure washing.

When it comes to cleaning a large commercial rice milling machine, is a large-scale job that consumes time and manpower. Depending on the season, it is said that cleaning must be done twice a month. For rice millers, they want the cleaning work of the rice bran that has accumulated in the rice milling machine becomes more efficient.

Rice bran can be efficiently removed by heating with a heater

Adhesion of rice bran to pipes is more likely to occur in winter than in summer. Humidity is the main factor. In many cases, the heater is not turned on in the building where the rice milling machine is installed during winter, and when the temperature is low, moisture adheres inside of the piping due to condensation. This moisture makes it easier for rice bran to stick to the rice during polishing.

To prevent rice bran adhesion, it is effective to reduce the humidity inside the piping. As a method, the piping is warmed from the outside to prevent moisture from getting inside. Some rice millers place an incandescent bulb near the pipes and heat the pipes with the heat (radiant heat) emitted from the incandescent bulbs. However, this method has the disadvantage of uneven heating. In addition, LED light bulbs, which emit almost no radiant heat, are used for floodlights, and there is no prospect of long-term use.

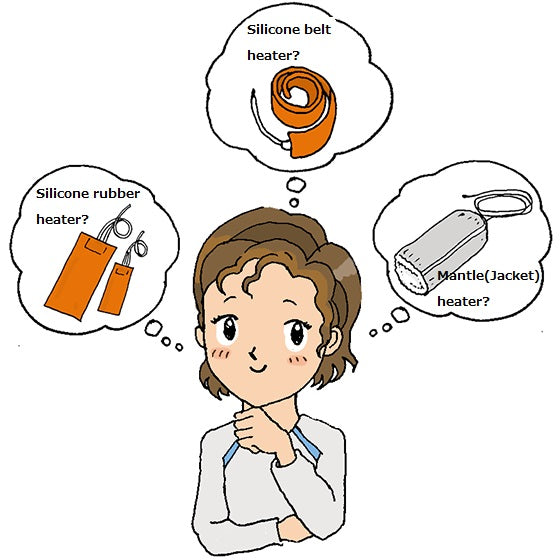

We would like to propose solution for rice bran adhesion for rice millers by heating the piping with a heater. By attaching a silicone rubber heater to the pipe and heating it, you can remove the moisture condensed inside the pipe. Since silicone rubber is flexible, it can adhere to the piping, enabling even heating. Therefore, the moisture inside the pipe can be uniformly removed.

↑Example of attaching a heater to the piping of a large rice milling machine

Our silicone spiral heater is one of our products suitable for heating pipes. A silicone spiral heater is a spiral heater that looks like a curled cord that you see on telephones. The feature is that it is easy to wrap around the pipe, and it is fixed with heat-resistant tape when wrapping. The maximum temperature that can be heated is 80 degrees.

![]()

↑Silicone Spiral Heater

To use a pipe heater, you also need a controller to control the temperature and a sensor to measure it.

At our company, we have prepared a product "Pipes Heater" which is a set of these.

In order to suppress the adhesion of rice bran like this time, the desired effect cannot be obtained unless the size of the heater is matched to the thickness and shape of the pipe. In other words, it is best made as a special-order item. Our company also sells the "Nukadama Buster" as a made-to-order heater for rice millers to prevent rice bran adhesion. We will make a dedicated heater that is perfect for your own rice milling machine. Please consider it.

We want to contribute to Japanese food culture through heaters.

Rice is an essential ingredient in our diet. Dishes using rice can be said to be a symbol of Japanese food culture. The menu, which combines rice, miso soup, and fish and meat dishes, makes you feel the Japanese food culture itself.

Providing consumers with safe and secure rice that is free from contamination is an important social contribution that will lead to the development of Japanese food culture. We believe that it is meaningful for our company to work on this social contribution. The heater plays an important role in cooking delicious rice with a rice cooker. In addition, it is a great honor to be able to contribute to Japanese food culture by contributing to rice polishing. We put our hearts into Japanese food culture, and are dedicating ourselves to making heaters.

![No more hesitation! How to choose an electric heater for industrial containers Part II [Bottom heating]](http://store.threehigh.com/cdn/shop/articles/choice_for_heaters_part2_0.png?v=1661486295&width=560)